Pipeline Welding Inspection: Cutting-Edge Approaches for Accurate Evaluations

Pipeline Welding Inspection: Cutting-Edge Approaches for Accurate Evaluations

Blog Article

Comprehensive Overview to Pipeline Welding Examination: Making Sure Integrity and Safety And Security in Pipe Construction and Upkeep

The stability and safety and security of pipes are paramount in today's facilities landscape, underscoring the critical function of welding inspection in pipe construction and upkeep. A comprehensive overview on this subject not just highlights the requirement of analyzing weld high quality yet likewise resolves the various examination techniques offered, such as ultrasonic and radiographic screening. By understanding typical issues and their implications, stakeholders can carry out ideal practices that make sure conformity and durability. Nevertheless, the intricacies entailed in welding inspection raising important questions regarding market standards and the developing technologies that may redefine these techniques.

Importance of Welding Inspection

Welding inspection plays a vital function in making sure the stability and security of pipeline systems. It serves as a fundamental procedure that confirms the top quality and dependability of welded joints, which are typically the most susceptible points in pipe building and construction. With methodical assessment, inspectors can recognize possible flaws such as fractures, porosity, and incomplete blend, which might endanger the architectural stability of the pipeline.

The importance of welding assessment extends beyond plain compliance with market standards; it likewise safeguards public wellness and the environment. Extensive inspections can enhance the durability of pipe systems, reducing the demand for costly repair services and downtime.

In addition to making certain security and conformity, welding examination cultivates a culture of top quality assurance within companies. By focusing on assessment throughout the welding process, business can construct a track record for reliability and excellence, inevitably resulting in raised customer confidence and service possibilities (Pipeline Welding Inspection). Thus, the significance of welding assessment can not be overemphasized in the context of pipeline building and upkeep

Key Welding Procedures

Numerous welding processes are employed in pipeline building and construction, each with its very own benefits and applications. Amongst one of the most extensively made use of approaches are Secured Steel Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Gas Metal Arc Welding (GMAW) SMAW is preferred for its adaptability and capability to perform well in numerous ecological problems, making it appropriate for field applications.

GTAW, typically described as Tungsten Inert Gas (TIG) welding, is acknowledged for its ability to produce top quality welds with outstanding control over heat input, making it perfect for thin-walled pipes and stainless-steel products. GMAW, or Metal Inert Gas (MIG) welding, provides high deposition rates and is efficient for large jobs, commonly utilized in the fabrication of pipes in regulated environments.

Additionally, Immersed Arc Welding (SAW) is used for its deep penetration and high performance, specifically in the building of large-diameter pipes. Each of these procedures adds to the general integrity and safety of pipeline constructions, enabling welders to pick the most appropriate approach based on product type, project demands, and environmental problems. Comprehending these key welding processes is essential for reliable pipeline welding examination.

Typical Defects and Their Influence

Porosity, characterized by small gas pockets entraped within the weld, damages the product and can result in leaks. Splits, which might happen due to thermal stresses or inappropriate air conditioning, can propagate and result in architectural failure under stress. Damaging, where the base metal is deteriorated along the weld grain, decreases the effective cross-section of the pipeline, raising the danger of fracture.

Insufficient go to the website combination occurs when the weld steel does not appropriately bond with the base metal, causing weak areas that might stop working under tension. Slag inclusion, the entrapment of non-metallic product within the weld, can also weaken the joint's stability. Identifying and addressing these flaws early in the building procedure is vital to guaranteeing the lasting dependability and safety of pipe systems, thus guarding both the facilities and the environment.

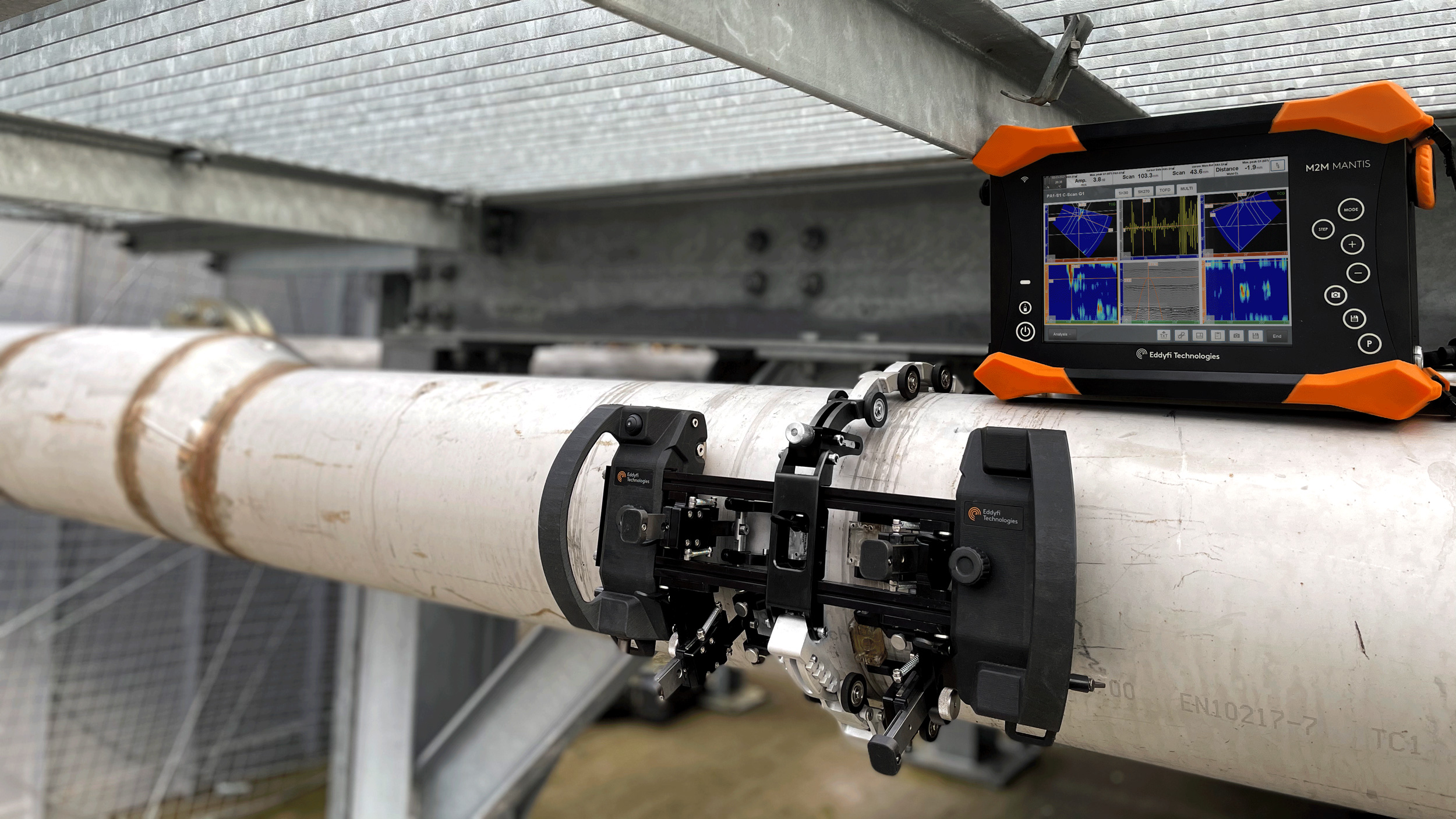

Examination Methods and Devices

Visual inspection is the initial line of defense, permitting examiners to identify surface area irregularities, imbalance, or other visible defects. Ultrasonic screening employs high-frequency audio waves to spot inner defects, giving precise deepness measurements and defining defects without damaging the weld. Radiographic screening utilizes X-rays or gamma rays to create pictures of the weld, enabling the identification of inner voids, fractures, or incorporations.

Magnetic particle screening is particularly efficient for detecting surface and near-surface discontinuities in ferromagnetic materials. This method entails applying a magnetic area and great iron particles to the weld, exposing flaws via the accumulation of bits at imperfection sites.

Along with these methods, specialized devices such as automated ultrasonic screening equipment and digital radiography systems improve examination accuracy and effectiveness, making certain an extensive examination of pipe welds throughout construction and maintenance.

Finest Practices for Compliance

Complying with ideal practices for compliance in pipeline welding assessment is vital for making certain the integrity and safety of the infrastructure. Organizations should establish an extensive top quality management system that lines up with market criteria such as ASME, API, and AWS. This consists of developing comprehensive welding procedures that specify the strategies, qualifications, and materials required for welders.

Regular training and certification of inspection employees are necessary to keep high expertise levels. Inspectors need visit their website to be acquainted with various non-destructive screening (NDT) approaches, consisting of ultrasonic testing, radiographic testing, and aesthetic examination, to effectively determine prospective issues.

Documentation plays an important function in conformity; keeping exact records of evaluations, weld treatments, and workers qualifications aids to guarantee traceability and liability. Arranged audits and testimonials of welding methods must be conducted to identify areas for improvement and guarantee adherence to established procedures.

Verdict

In final thought, the execution of strenuous welding inspection protocols is critical for guaranteeing the stability and safety and security of pipeline building and construction and maintenance. Continual enhancement in examination processes will certainly add to the long life and integrity of pipe systems, emphasizing the critical role of welding inspection in the market.

The integrity and security of pipelines are vital in today's facilities landscape, highlighting the vital function of welding evaluation in pipe building and construction and maintenance. Comprehending these key welding processes is crucial for reliable pipeline welding inspection.

Sticking to finest practices for compliance in pipe welding assessment is important for guaranteeing the integrity and safety and security of the facilities.In final thought, the implementation of extensive welding inspection procedures is extremely important for making sure the honesty and safety of pipeline construction and maintenance. Continuous renovation in evaluation processes will certainly contribute to the durability and dependability of pipeline systems, underscoring the vital function of welding examination in the market.

Report this page